Hotline: +84 902 588 891

In recent years, laser welding machines have become standard equipment in jewelry shops, crafting workshops, and small detail processing facilities. This technology helps create exquisite welds, nearly invisible weld lines, high durability, and minimizes surface scorching – something that traditional welding methods struggle to achieve. However, although laser welding machines bring outstanding benefits, operators still need to master the process and techniques to use them safely, effectively, and to extend the equipment’s lifespan.

This article is designed specifically for those who are learning how to use laser welding machines methodically, from operating principles, handling procedures, and parameter settings to safety notes and common errors. This is also a suitable reference document for jewelry shops that have newly invested in machines or processing workshops looking to standardize their internal processes.

Laser welding machines operate based on the mechanism of focusing high-energy light into a very small point, creating extremely high temperatures in a very short time. When the energy is sufficient, the metal surface melts and bonds together, creating a seamless weld. The most important aspect of laser technology lies in the ability to focus energy precisely, preventing heat from spreading, so the item is hardly deformed.

In the jewelry industry, this is particularly important because products often have small sizes, exquisite details, thin thickness, and require very high aesthetics. With materials such as 18K gold, 24K gold, 925 silver, platinum, or white gold, craftsmen using laser welding machines can perform operations such as joining wires, welding hooks, patching blowholes, reinforcing stone settings, or repairing thin details without affecting the overall structure.

Understanding the material type and how it conducts heat is the key to setting standard parameters. For example, silver conducts heat very strongly, so it is harder to weld than gold or platinum; if the craftsman increases the power excessively, the product may have burnt edges or holes. Conversely, if the power is too low, the weld will not adhere. Therefore, mastering the principles is the foundation for all subsequent laser welding operations.

Before starting any welding shift, checking the machine is a mandatory step. The operator needs to ensure a stable power supply, and that the cooling system and air filter are in good condition. The welding chamber needs to be cleaned to avoid dust or oxidation adhering to the protective lens, affecting the laser beam.

>> See more: Guide to cleaning welding machines at home properly

The protective lens (filter) is the most important part because it plays the role of protecting the user’s eyes. If the lens is scratched, burnt, or discolored, the intensity of the laser beam passing through may be unstable, leading to a risk of retinal damage. Therefore, laser welding machine operators need to check carefully before each working session.

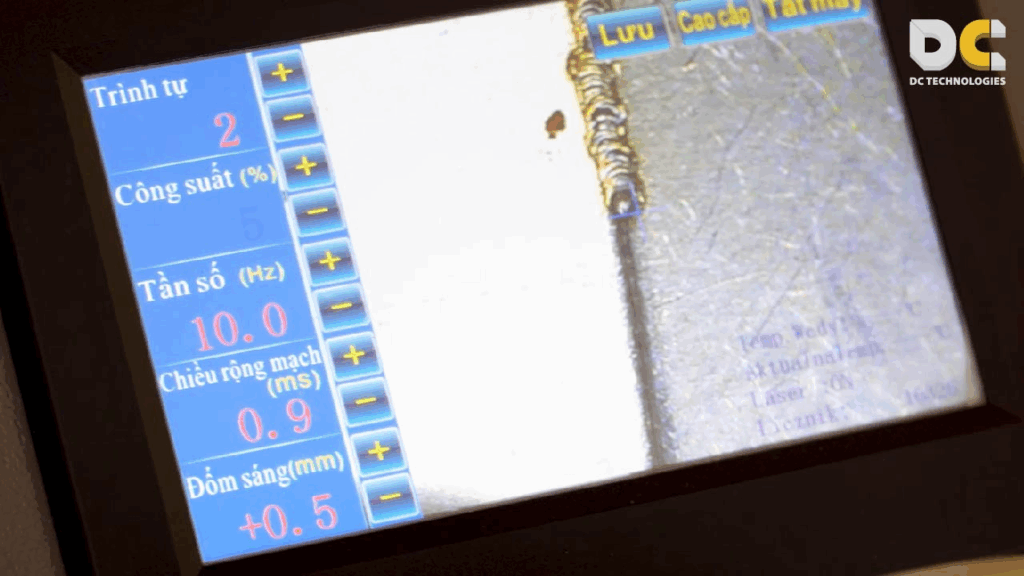

The craftsman will adjust four important parameters: power, beam diameter (spot size), pulse duration, and shooting frequency. Each type of material has different requirements:

One of the common mistakes beginners make is applying “the same formula for every material,” leading to burnt welds, worn threads, or visible weld marks. For this reason, before welding on the real product, the craftsman should test on a sample piece of metal to observe the reaction and readjust accordingly.

>> See more: LaserX 200W welding machine welds many types of materials in the jewelry industry

After setting parameters, the user places the product into the welding chamber, selects the exact position, and keeps their hands steady. Hand shaking or jerking will make the weld line deviate, affecting aesthetics. The laser beam needs to be directed perpendicular to the product surface for the best adhesion.

During the welding process, the craftsman observes through the microscope and adjusts the distance appropriately. A very small wrong manipulation can also leave marks on the surface, so practicing hand stability and keeping a steady rhythm is extremely important.

High-power laser beams can be dangerous if not handled correctly. First, the eyes are the most vulnerable part. Looking at the laser beam directly or through reflective surfaces can lead to retinal burns. Therefore, specialized protective glasses with the correct wavelength must be worn throughout the operation time.

In addition, the welding process generates metal fumes, sometimes containing toxic compounds. The welding environment must have a fume extraction or good ventilation system to reduce respiratory risks. Some high-end devices have integrated fume filters, but many workshops still need additional auxiliary systems.

Finally, the craftsman needs to remember that the detail after welding can still be very hot. Many burn cases occur just because of accidentally touching the product immediately after welding. Waiting for the product to cool or using tweezers is a safer option.

Beginners often encounter errors such as pitted, blackened, or non-adhering welds. Pitted welds are usually due to a dirty surface or parameters being too strong for the material. Blackening occurs when the spot size is too large or the pulse duration is too long. Meanwhile, a non-adhering weld indicates that the power is too weak or the welding area has not been cleaned.

If the machine operates unstably or the beam is uneven, it may be related to a dirty protective lens, the cooling system, or the laser source needing maintenance. For deeper technical errors, it is best to contact the machine supplier for inspection.

Jewelry repair shops, jewelry crafting workshops, small craft facilities, the optical industry, watches, and even precision mechanical processing workshops can all use laser welding machines. Places that require beautiful, thin, nearly invisible welds will benefit greatly from this technology. Instead of spending hours correcting and polishing like traditional methods, lasers shorten the processing time to just a few minutes.

>> See more: Laser welding technology in jewelry and mechanical processing

With over two decades of serving the jewelry-industrial sector in Vietnam, DC Technologies not only provides equipment but also accompanies customers through training services, technical support, and long-term maintenance. The laser welding machine lines distributed by DC Technologies are all strictly quality-checked and suitable for many budget levels.

New customers often highly appreciate DC providing hands-on training services, detailed instructions from setting parameters to manipulation tips for the most beautiful welds. This is the difference that helps DC Technologies become the priority choice of thousands of jewelry shops and production workshops nationwide.

Hotline: (+84) 908 727 235

Showroom: 87 Nghia Thuc, An Dong Ward, Ho Chi Minh City.

HUTECH High-Tech Center: 4th Floor, HUTECH Building, D1 Street, High-Tech Park, Tang Nhon Phu Ward, Ho Chi Minh City.

Hanoi Office: No. 22B O2, Linh Dam Peninsula, Hoang Liet Ward, Hanoi City.