Hotline: +84 902 588 891

Unlike handmade jewelry production, today we can mass-produce jewelry with the same design and consistent quality. To achieve this, the wax model creation step is crucial; from an initial model, a wax injector allows you to produce hundreds of identical models to match production quantities. The MJ-01-C13A wax injector is an incredibly powerful tool in the wax modeling phase due to its advantages over other wax injectors on the market. In today’s article, let’s explore the strengths of the MJ-01-C13A wax injector and tips for maintaining the machine.

The MJ-01-13A wax injector, a product by the Italian brand Masterix, has won over customers with the following features:

High Pump Capacity:

Using the Master Inject wax injector boosts productivity and saves time. The machine’s capacity reaches 300 products per hour and over 2000 products per day, thanks to its automatic injection mode that doesn’t require button pressing.

Ability to Inject Complex Models:

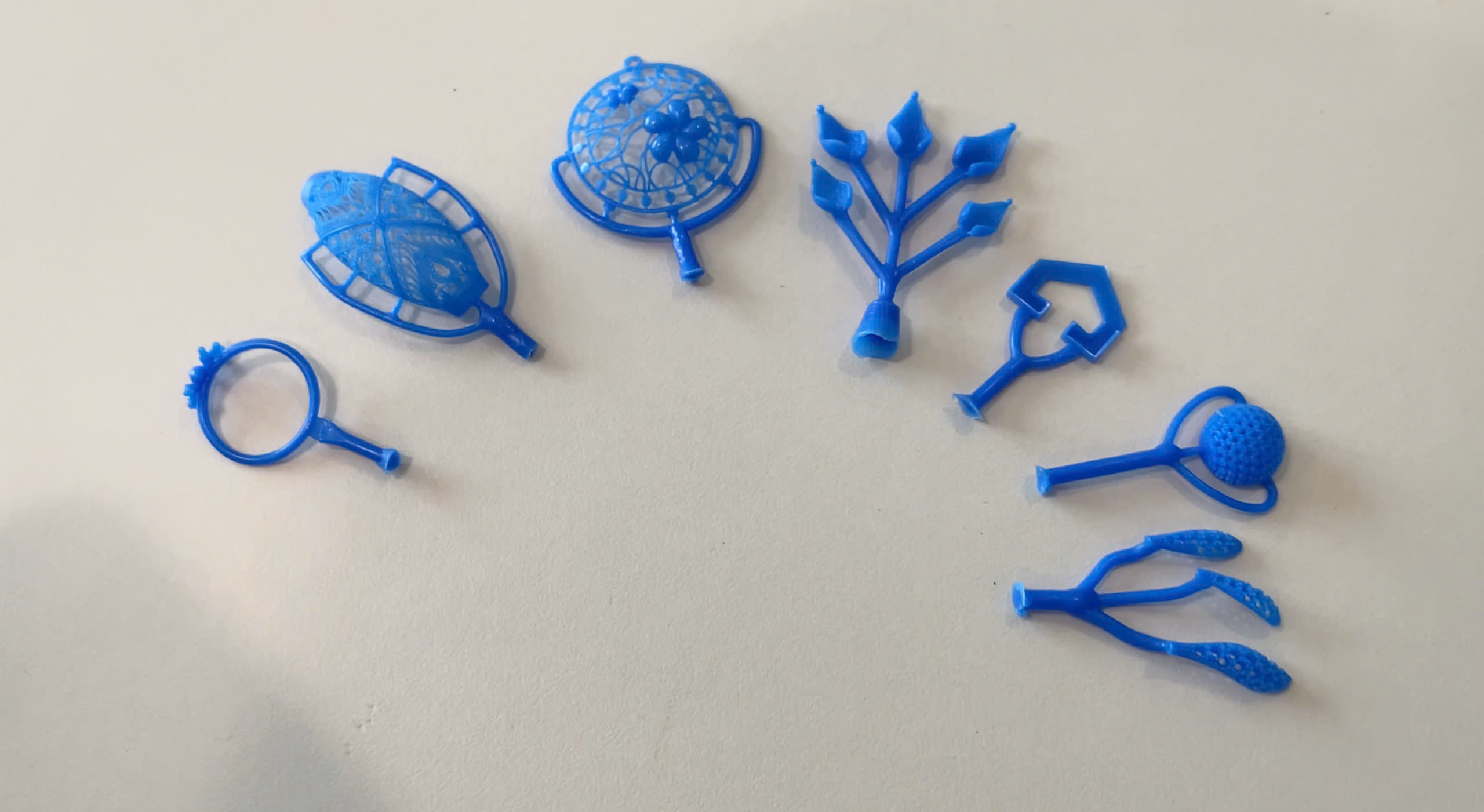

The machine incorporates advanced technology, with the MJ-01-C13A featuring an automatic injection program that saves ⅔ of the injection time to increase output. Master Inject is confident in its ability to handle complex wax models due to its vacuum wax tank design, which removes air bubbles, ensuring smooth wax flow. Its advanced piston pump system provides better injection quality, creating wax models with high stability and accuracy.

The machine ensures that injected wax models consistently meet quality standards by using vacuum injection to remove air from the mold effectively. If the vacuum process does not reach 100%, the injection won’t proceed; only when a 100% airtight seal is achieved will the machine inject. This allows the wax to penetrate every detail of the product, especially for small, intricate models.

One of the strengths of the Masterix Inject machine is its simple operation and easy cleaning process. The component that requires regular cleaning is the wax tank because, after some time of use, the wax injection system may become clogged, causing the machine to produce defective products.

If you notice the machine is producing substandard items, check the wax tank and prepare to clean it. Generally, you only need to clean the wax tank once every 6 months or a year. Furthermore, the cleaning process is straightforward, and here’s the step-by-step guide for cleaning the MJ-01-C13A wax tank from DC New Technology Company:

Tools: Prepare a wax-catching tray and paper towels.

Step 1: Open the wax tank by pressing the “Open Tank” button on the machine screen.

Step 2: Place the prepared tray underneath to catch any wax flowing from the rear.

Step 3: Close the tank, refill it with new wax, and continue using the machine.

That’s how you clean the wax tank of the Masterix Inject wax injector. For the machine body, simply wipe it with a cloth after each use. If you’re still unclear about how to clean the machine, watch the tutorial video from DC TECH’s technician below.

Regular cleaning and checking the machine after each use will ensure its durability over time. Furthermore, the warranty period when purchasing the machine from DCTECH is up to 3 years for consumable parts and up to 5 years for the machine’s circuit board components.

As discussed in the article, the Masterix Inject machine is suitable for those looking for a wax injector to create wax models, especially ideal for beginners due to the machine’s strengths.

The Masterix Wax Injector is distributed and serviced by DC. If you’re looking for a high-quality, easy-to-use wax injector, contact DC through the hotline or send a message on DC’s Fanpage for consultation on wax injectors and other products for the jewelry industry. We pride ourselves on 24 years of experience in the jewelry industry, offering not only quality products but also technology transfer to our customers.