Hotline: +84 902 588 891

Laser welding technology, especially specialized laser welding machines designed for industrial applications has become the optimal solution thanks to its ability to create ultra-fine, clean, and highly durable welds far superior to traditional welding methods. This article will help you understand what a laser welding machine is, its structure and operating principles, its outstanding advantages, and an introduction to the advanced MEGA 6.0 laser welding system that is widely chosen by modern manufacturing businesses.

Laser welding machine is a device that uses a high-energy laser beam to melt material at the targeted welding point, creating precise, clean, micro-sized welds with exceptional strength. This technology is increasingly replacing many traditional welding methods thanks to its superior accuracy, refined processing capabilities, and high welding speed.

A desktop laser welding machine consists of 9 key components:

The laser source is the most critical component, directly determining weld quality. Desktop laser welding machines commonly use diode-pumped Nd:YAG or fiber lasers, which provide strong, stable, and precise pulse output. This is where the high-energy laser beam is generated to melt the material at the welding point.

The pulse generation system controls the laser’s energy and pulse frequency. By adjusting pulse amplitude, pulse width, and output power, the operator can modify weld depth, smoothness, and speed. The power supply ensures system stability and provides sufficient energy for all machine components.

>> Read more: DADO & DADO 2.0 Benchtop Laser Welders – specialized for the jewelry industry

The optical system includes mirrors, focusing lenses, and spot-size adjustment modules. The laser beam from the source is guided and concentrated into an extremely fine focal point, enabling highly precise welds with minimal spatter and reduced heat-affected zones.

The welding chamber is the enclosed workspace where the workpiece is placed. It typically features a sealed design with an access door and bright illumination. Inside the chamber are the laser welding head, observation system, and a work platform to keep the piece stable during welding.

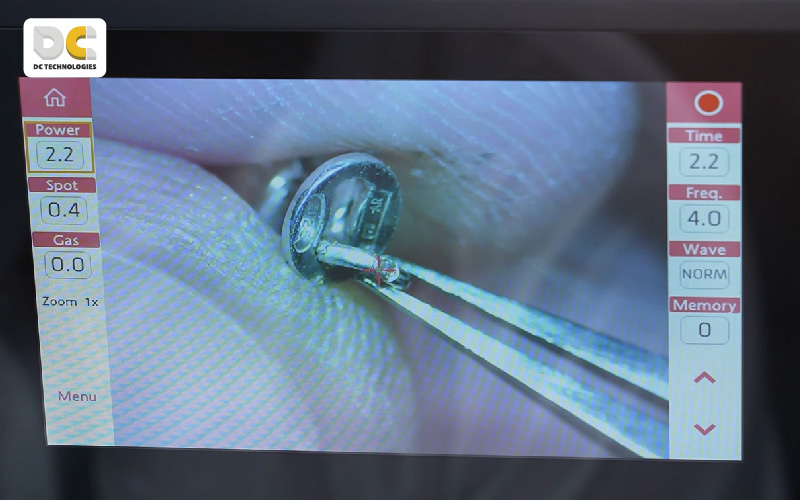

This essential component allows the operator to clearly view small, intricate details during the welding process. Optical microscopes or CCD cameras provide high-resolution, magnified images, ensuring precise weld positioning and exceptional craftsmanship.

Desktop laser welding machines are equipped with water or air cooling systems to keep the laser source at a stable temperature. This helps extend component lifespan, maintain consistent performance, and prevent overheating that could interrupt operation.

The control panel allows the operator to set welding parameters such as pulse energy, pulse width, frequency, spot size, and preset modes. Many modern systems use intuitive touchscreen interfaces for easier and more accurate adjustments.

Argon gas is often delivered directly to the weld area to minimize oxidation, resulting in cleaner, brighter, and stronger welds. This component is especially important for jewelry welding and applications requiring high aesthetic quality.

The machine frame is built to be sturdy, vibration-resistant, and protective of internal components. Additional auxiliary features include cooling fans, smoke filters, internal LED lighting, and connection ports—all contributing to durability, safety, and smooth operation.

The laser source (Nd:YAG or fiber laser) produces a beam of highly concentrated light. The pulse generation system controls power, pulse width, and frequency to ensure the laser delivers the appropriate energy level for each material type and thickness.

After being generated, the laser beam is guided through the optical system. Focusing lenses concentrate the beam into a spot as small as 0.2–1 mm in diameter, creating extremely high temperatures at that point—often reaching several thousand degrees Celsius.

At the focal point, the high-intensity laser energy melts the metal rapidly without affecting surrounding areas. This is why laser welding offers a minimal heat-affected zone, reducing deformation and discoloration of the product.

>> Read more: MS 3.5 Laser Welding Machine – a specialized welder for the jewelry industry

As the material melts, the surfaces fuse together through metallurgical bonding. Once the laser pulse stops, the molten pool solidifies quickly, forming a clean, precise, and highly durable weld.

During welding, Argon gas is directed onto the weld area to:

– Prevent surface oxidation

– Enhance surface brightness

– Increase weld strength

This is especially important for welding gold, silver, platinum, stainless steel, and other precious metals.

The operator views the work area through a microscope or camera, enabling precise control of weld position, energy, and pulse duration. This level of visibility is crucial for producing intricate, high-quality welds—particularly in the jewelry industry.

The MEGA 6.0 is equipped with an Nd:Ce:YAG laser source delivering an average power of 100W, a maximum pulse energy of 255J, and a peak power of 11 kW, enabling the generation of an extremely powerful and stable laser beam.

Thanks to its ability to deliver high energy in very short pulses, the machine can easily handle thick components and highly reflective metals such as silver or platinum while maintaining exceptional precision and sharp weld quality.

The Gaussian Smooth Spot technology is one of the machine’s standout advantages, optimizing the quality of the weld spot. This technology produces a uniform, perfectly rounded laser spot without porosity, reducing burr formation and enhancing the overall aesthetics of the weld.

In particular, when working with silver – metal with a high reflectivity rate—Gaussian Smooth Spot helps minimize energy loss while ensuring weld stability and consistent penetration depth.

In addition to the standard model, the MEGA 6.0 offers an optional 3D Vision observation system that replaces the traditional microscope. This technology provides a stereoscopic viewing angle of the welding area, reducing eye strain during long working sessions.

Furthermore, its intuitive control interface, full-color touchscreen, and integrated joystick inside the welding chamber allow operators to work faster and streamline parameter setup time.

The system integrates a direct Argon gas inlet at the welding point, helping minimize oxidation, preserve the metal’s natural brightness, and enhance joint durability. The use of Argon is especially critical in the jewelry industry, where welds must retain their original color, avoid burn marks, and maintain the product’s overall value.

The dual cooling system—combining water cooling with air cooling – ensures the laser source remains at an optimal temperature even during high-intensity operation. This allows the machine to maintain stable performance, extend component lifespan, and provide maximum safety for the operator.

Additionally, the cooling system effectively prevents overheating, enabling continuous, long-duration workflows without interruption.

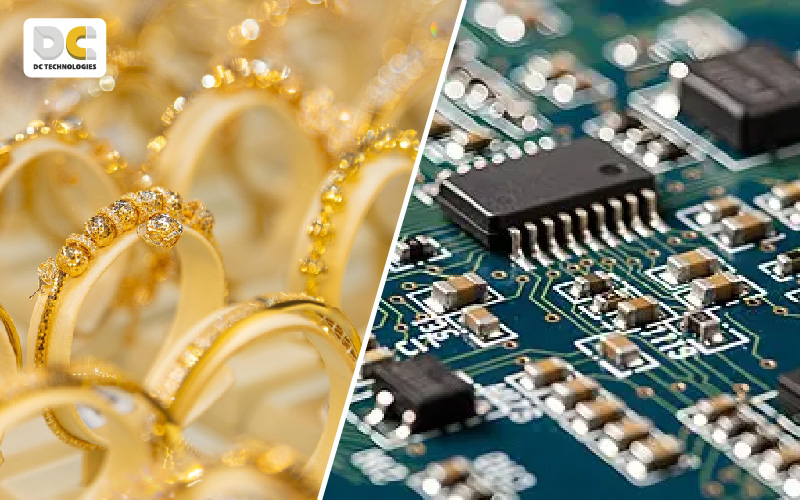

The MEGA 6.0 welding system is engineered specifically for jewelry shops and manufacturing workshops, thanks to its ultra-fine micro-welding capability, high precision, and minimal heat distortion on precious metals.

The machine works exceptionally well with gold, silver, platinum, titanium, and even gemstone-mounted jewelry. Delicate repair tasks – such as restoring thin details, tightening stone prongs, welding tiny joints, or assembling ultra-thin components – are completed quickly, cleanly, and safely.

>> Buy now: MEGA 6.0 Laser Welding Machine at DC Technologies

For electronic component manufacturing, the machine ensures clean, precise, and stable welds thanks to its low heat-affected zone.

It is ideal for welding heat-sensitive parts such as sensors, connectors, battery tabs, ultra-fine wires, and components requiring high stability. With its precise energy control, the machine significantly reduces component damage and enhances overall product durability.

When investing in a laser welding machine, choosing a reputable supplier is essential. The supplier should provide official distribution certification, clear commitments regarding quality and origin, and complete technical documentation. Key factors to consider include:

– After-Sales Policy: Laser machines require regular maintenance, so select a supplier that offers technical support, replacement parts, and warranty services.

– Technical Support and Training: The provider should advise on appropriate parameters (power, laser type) for your specific needs and provide safe operation training.

– Quality and Origin: Verify the laser source (e.g., IPG, Raycus), the origin of components, and whether the machine meets the advertised quality standards.

DC Technologies offers a wide range of leading laser machines in Vietnam and across Southeast Asia, suitable for businesses of all sizes—from small workshops to large enterprise chains. All models feature high precision and user-friendly operation:

– Exceptional Precision: The laser beam produces an ultra-fine spot, allowing highly accurate welds on intricate details.

– Versatile Applications: The machines can weld gold, silver, platinum, titanium, steel, stainless steel, copper, and many other metals. They also handle ultra-thin parts and heat-sensitive materials effectively.

– Professional Service: DC Technologies provides not only high-quality products but also dedicated after-sales service, training, and comprehensive technical support.

When purchasing a laser welding machine from DC Technologies, you can expect:

– 100% genuine, certified products

– Official warranty and long-term technical support

– Free on-site training and setup assistance

– Access to a professional technical team in Vietnam

– Flexible payment and installment options

In addition to providing advanced technological solutions, DC Technologies has developed a comprehensive service system to optimize production efficiency for businesses. Their experienced technical team assists with installation, operational training, and parameter fine-tuning to ensure the machines perform reliably from day one. DC Technologies offers official warranty, scheduled maintenance, component replacement, and tailored consultancy based on each client’s production requirements.

Furthermore, businesses receive support in designing workflows, implementing automation solutions, and optimizing costs—helping improve long-term productivity and product quality. This full-service standard is part of DC’s commitment to being a trusted strategic partner for enterprises across the country.

Conclusion

Laser welding is gradually establishing itself as a critical technology in industries that demand high precision and exquisite aesthetics. With its modern design, powerful performance, and minimal heat-affected zone, this technology delivers superior weld quality that is difficult to achieve with traditional methods.

In particular, the Elettrolaser MEGA 6.0 stands out with high performance, advanced Gaussian Smooth Spot technology, and a dual cooling system, making it an ideal choice for jewelry workshops and high-tech enterprises.

If you are looking for a genuine, durable, safe, and high-performance laser welding machine, DC Technologies is ready to support you from consultation and installation to training and long-term technical assistance. Investing in the right machine and choosing a trusted supplier will help your business produce finer, high-quality products, enhance service standards, and boost competitiveness in the market.

Contact DC Technologies today for expert advice and a completely free machine demo!

Website: https://dctech.com.vn/

Hotline: 0901 958 318

Showroom: 87 Nghia Thuc Street, An Dong Ward, Ho Chi Minh City.

4th Floor, HUTECH Building, D1 Street, Saigon Hi-Tech Park, Tang Nhon Phu Ward, Ho Chi Minh City.

22B, Block O2, Linh Dam Peninsula, Hoang Liet Ward, Hanoi City.

Frequently asked questions:

What is laser welding machine?

Laser welding technology for jewelry and mechanics explained