Hotline: (+84) 901 958 318

Jewelry, in particular, and fine jewelry products in general, always captivate customers with their beauty. To create high-quality and aesthetically pleasing products, jewelers must pay attention to numerous factors throughout each stage of production. If your products have a high defect rate or do not meet the desired standards, you might not yet be aware of the key factors that determine product quality in jewelry manufacturing. Join DC Tech as we explore the 4 essential conditions that help produce high-quality products in the jewelry industry.

To create a piece of jewelry, numerous different stages must be completed. Each step in this process impacts the subsequent steps and the final product’s quality. The first stage is model creation; once we have the 3D design file, we need to produce a prototype using resin. Therefore, the first determining factor is the quality of the resin.

Resin is the material used to create 3D resin models, which is the first step in the jewelry production process. Therefore, choosing high-quality resin contributes to the beauty of the cast jewelry. To achieve this, the resin must meet three criteria: compatibility with 3D printers, high burn-out capability, and minimal ash residue after burning.

Refer to the article about Resin here.

In addition to choosing a resin with good casting properties, selecting the appropriate investment powder is equally important, as the plaster mold plays a crucial role in producing a beautiful cast model. To achieve a quality cast model, a high-quality plaster mold is needed, because resin, when burned, leaves behind ash.

This ash requires a long soaking time at high temperatures to be fully eliminated from the plaster mold. Therefore, the plaster used for resin molds must have extremely high heat resistance. If the plaster’s heat resistance is too low, it can crack when subjected to high temperatures and extended soaking periods.

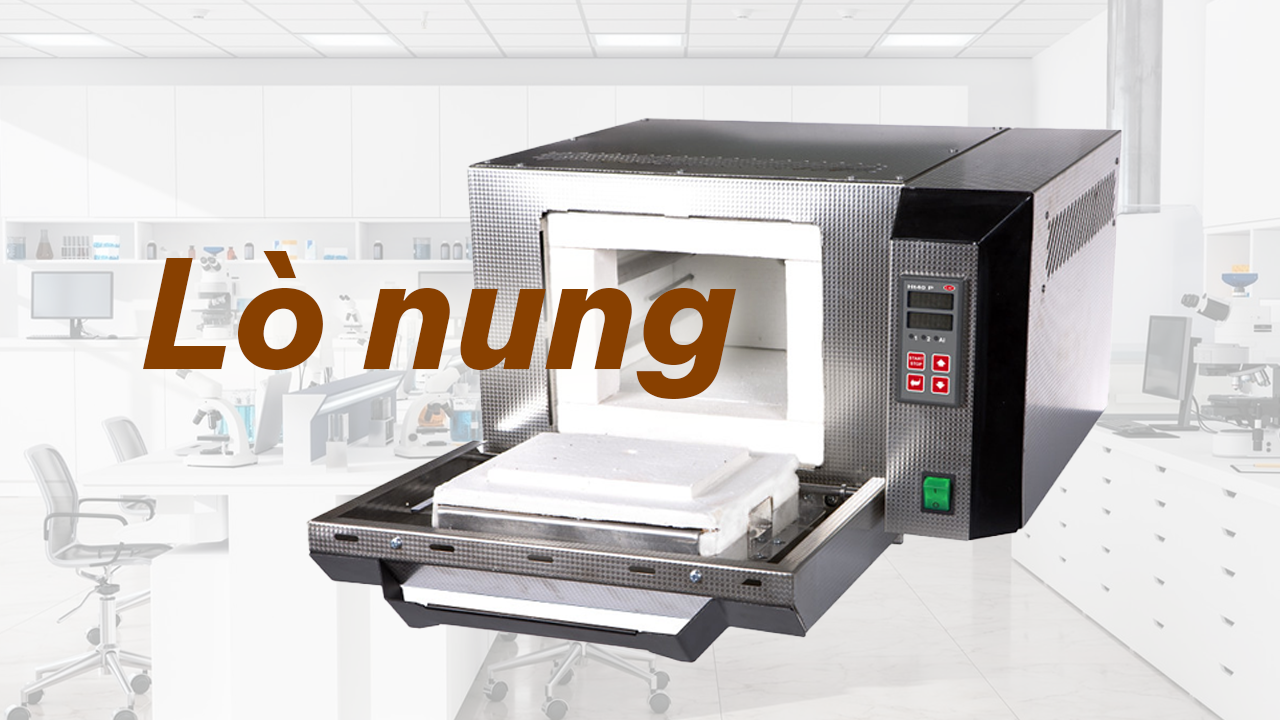

As mentioned above, the secret to achieving a high-quality plaster mold lies in the plaster kiln. So why does the kiln affect the quality of the plaster mold? A high-quality plaster mold must achieve maximum hardness; otherwise, when molten metal is poured into the mold, the interior areas of the mold are prone to erosion. This is especially true for delicate parts where the plaster thickness is very thin. If the plaster does not reach optimal hardness, it can easily erode and damage the structure in those areas. Additionally, if the plaster does not have sufficient hardness, it can react with the molten metal, leading to surface defects in the cast model.

To achieve the highest hardness of plaster molds, the kiln must have a sufficiently high power capacity to generate high enough temperatures and must be well-sealed to prevent heat loss. Additionally, a high-power kiln will greatly support the complete combustion of the resin ash.

Moreover, a stable kiln temperature is one of the favorable conditions for the plaster mold to reach optimal hardness and for the resin ash to be fully burned off as quickly as possible. To maintain a stable kiln temperature and minimize significant temperature fluctuations, the kiln’s temperature controller must have an inverter function to control the power output of the heating elements. The power capacity of the kiln and its temperature control system are key factors that create the distinction between different kiln segments in the market.

To create a perfect cast product, in addition to having a high-quality plaster mold that can withstand high temperatures in the furnace, the key factor to achieving a flawless cast is the casting machine you use. A high-quality casting machine is not just a tool that supports the casting process, but it is also the instrument that determines whether you can conquer the most complex design patterns and ensure meticulous finishing for every detail.

When using a quality casting machine, common issues like missing details or air pockets inside the product are significantly reduced, addressing the drawbacks that traditional manual casting technology cannot guarantee. The technical limitations of manual casting processes make it difficult to control product quality, especially when working with complex patterns.

Automatic casting machines offer many superior advantages. One of the key highlights is their ability to control the melting process of the metal while protecting it from oxidation, keeping the metal quality at its best. Additionally, the temperature during the melting process is tightly controlled and stable. Temperature stability is a critical factor because if the temperature fluctuates suddenly, the metal may be damaged or fail to achieve the desired strength.

The most obvious difference between automatic casting machines and traditional manual casting technology lies in the process of pouring metal into the mold. For automatic casting machines, this process is not just about pouring metal; it combines vacuum and compression pressure. This allows the molten metal to easily penetrate every tiny corner inside the plaster mold, ensuring the cast is completed meticulously and accurately, even with the most intricate details.

Not only that, the vacuum environment and compression pressure also help the molten metal solidify with higher density and uniformity compared to manual casting. This results in greater mechanical strength for the product, while minimizing common issues like air pockets or voids inside the cast. The finished product will have a smooth surface without any hollows, ensuring both aesthetic appeal and long-lasting durability.

In addition, automatic casting machines help optimize the production process by increasing stability and efficiency. With a quality casting machine, the time to complete a product is shortened, and production output is increased. This not only brings economic benefits but also ensures consistency and stability in product quality, something manual casting technology can struggle to achieve.

In summary, using automatic casting machines not only improves product quality but also creates a significant advantage throughout the entire production process. From casting complex designs to minimizing product defects, automatic casting machines are truly the optimal solution for businesses looking to achieve top-tier quality and high production efficiency.

Through this article, DC Tech hopes you now know the secret to creating high-quality jewelry products. Jewelry that is both high-quality and beautiful is the key to winning the hearts of any jewelry lover. Therefore, DC Tech is committed to providing the best machinery to help customers create products that will satisfy their own customers. DC Technology Joint Stock Company is proud to have over 24 years of experience in the industry and is a trusted name in the market, offering a wide range of high-tech machinery for the jewelry sector.