Hotline: +84 902 588 891

In an era when product personalization has become a leading trend, jewelry is no longer just decoration but a symbol of identity. Modern customers want unique pieces that carry their own mark, from rings and bracelets to pendants. To meet this demand, laser engraving technology has emerged as a perfect solution for the jewelry industry, creating intricate, precise, and durable details.

In the article below, DC will explain why laser engraving technology has become an essential factor in the personalization journey of modern jewelry.

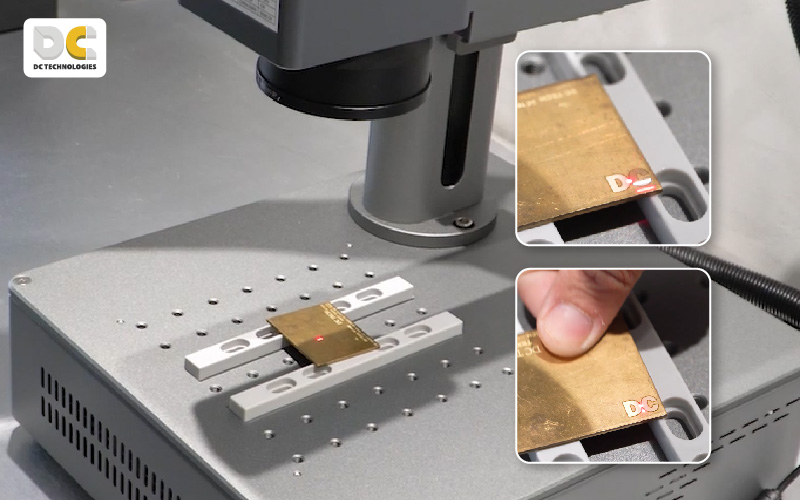

Laser engraving technology is a surface processing method that uses a highly concentrated laser beam to directly impact the material. At the point of contact, the intense heat from the laser warms, vaporizes, or alters the chemical structure of the surface, creating sharp, permanent, and exceptionally precise markings.

Unlike traditional mechanical engraving methods, laser engraving is non-contact, causing no vibration or physical pressure that might affect the material’s structure, making it highly suitable for jewelry with small sizes and intricate details.

>>See more: 20W Compact Fiber Laser Engraving Machine – High Power

Laser engraving technology works by focusing a high-energy laser beam onto an extremely small point on the material’s surface. The heat at the focal point rises rapidly, causing the material to evaporate, melt, or change color. This process creates sharp, consistent engraving lines with almost perfectly accurate depth, depending on the material and machine settings.

The entire engraving operation is computer-controlled through specialized software (such as EZCAD), allowing users to design patterns, text, or images and send commands directly to the machine. Thanks to this automation, the laser can engrave extremely intricate details and repeat them accurately across multiple products without misalignment or errors, unlike manual methods.

According to PW Consulting, in an era that values individuality and personal experiences, personalized jewelry has become a top choice for Millennials and Gen Z. Deloitte states that 45% of Millennial consumers strongly prefer customized products because they allow them to express their own identity. Name-engraved rings, necklaces marking special dates, or pieces with personal details are more than accessories; they represent each person’s story.

Beyond aesthetic appeal, personalized jewelry is deeply connected to emotions and memories. These pieces often become symbols of relationships and meaningful milestones such as birthdays, graduations, or anniversaries.

As a result, personalized jewelry is not just a trend but a way for individuals to create their own signature. It brings together beauty, meaning, and emotion in a piece that carries the story of its owner.

In the modern jewelry industry, laser engraving technology has become an indispensable tool, especially as the demand for personalization and intricate details continues to grow.

The most common application of laser engraving is inscribing names, messages, or personal symbols on rings, bracelets, pendants, and other personalized jewelry pieces.

Lasers are also used to create intricate patterns, QR codes, or brand logos on products, serving both decorative and authentication purposes.

Additionally, laser technology supports mass production while maintaining precision and aesthetic quality, allowing jewelry workshops to increase output without compromising craftsmanship.

For thin, small, or curved pieces, laser engraving helps prevent material damage, avoids scratching gemstones, and preserves the original shape of the product.

Laser engraving machines allow the creation of extremely small and complex details that are difficult to achieve by hand. Every engraving is uniform and precise, meeting high design requirements—from signatures, patterns, and logos to extremely delicate motifs.

Lasers target only the exact point to be engraved without scratching or deforming the metal or gemstones. This is especially important for thin, small, or intricately detailed pieces, where manual methods are prone to damage.

With computer control, lasers can engrave multiple pieces consistently at once. Compared to manual methods, productivity is significantly higher while maintaining quality, allowing jewelry workshops to complete orders faster and reduce operating costs.

Modern customers want their jewelry to carry personal touches such as names, anniversaries, symbols, or unique patterns. Laser engraving brings these requests to life quickly and accurately, enhancing the emotional value of the products.

Thanks to these advantages, laser engraving machines are no longer optional but essential tools that help jewelers maintain creativity, expand personalized services, and gain a competitive edge in the increasingly dynamic jewelry market.

The first step is to determine the primary material used in the workshop. For precious metals such as gold, silver, or titanium, machines that use Fiber or MOPA sources (Fiberlux NANO, Luxmark S, Luxmark M & TOP) deliver sharp and durable engravings. For non-metal materials such as mother of pearl, wood, high-grade plastics, or glass, the Luxmark M-TOP 200 CO₂ provides refined engraving results without burning the edges. Choosing the right laser source ensures optimal quality and prolongs machine lifespan.

Jewelry pieces are typically small and require highly detailed engraving with precision around ±0.01 mm. The Fiberlux NANO series with the 60W MOPA version allows advanced pulse-duration control, enabling extremely fine engraving on intricate and curved components.

Modern laser engraving machines usually come with professional software that supports multiple design formats such as SVG, DXF, AI, PLT, and BMP, while also integrating CNC functions and design storage. This allows workshops to operate efficiently, manage complex projects, and meet various personalization requests.

The size and flexibility of the machine influence workshop layout and the range of products that can be engraved. Compact machines like the Fiberlux NANO are ideal for small workshops, fine jewelry pieces, or personalized orders. Meanwhile, larger machines such as the Luxmark M & TOP, W15, and W72 with spacious working chambers, motorized axes, rotary attachments, and automatic pallet handling systems are suitable for mass production, large components, or continuous engraving tasks while maintaining high accuracy and speed.

A quality laser engraving machine comes with warranty maintenance and prompt technical support In case of malfunctions or software updates the workshop can continue production without interruptions.

When investing in a laser engraving machine for a jewelry workshop, choosing genuine equipment from a reputable supplier is key to ensuring quality and processing efficiency.

DC Technologies provides genuine laser engraving machines, guaranteeing everything from intricate details to mass production. With over 20 years of experience and partnerships with major jewelry brands like PNJ, DOJI, and SJC, DC Công Nghệ Mới confidently delivers the best experience for its customers.

Jewelry personalization is no longer a temporary trend but has become a new standard in the modern jewelry industry. Customers increasingly seek pieces that carry personal touches, reflecting their personality, preferences, or special memories. To meet this demand, laser engraving technology plays a crucial role, enabling the creation of intricate, precise, durable details that can be easily customized according to customer requests, from engraved names and symbols to complex patterns.

The application of laser engraving technology not only enhances product quality but also helps jewelry workshops increase productivity, reduce the risk of damage, and expand creative possibilities. For workshops and artisans looking to adopt this technology, DC Technologies is a trusted partner, providing genuine laser engraving machines with professional warranty and technical support, along with customized solutions to meet customer needs.

For more information, visit the link below: