Hotline: +84 902 588 891

In the era of rapidly developing technology, modern mechanical devices and machinery have been created to support people in improving efficiency and accuracy in production. The jewelry industry is no exception: jewelry welding machines have been developed to help jewelers create precise welds on small, thin components and near gemstones, which industrial welding machines with high power and wide heat-affected zones find difficult to perform.

Understanding the difference between these two types of machines is an important step in selecting the appropriate equipment, ensuring product quality, and optimizing time and cost for a workshop or jewelry studio.

In this article, DC Technologies will help you clearly distinguish between the two types of machines, supporting you in making the optimal choice for your needs.

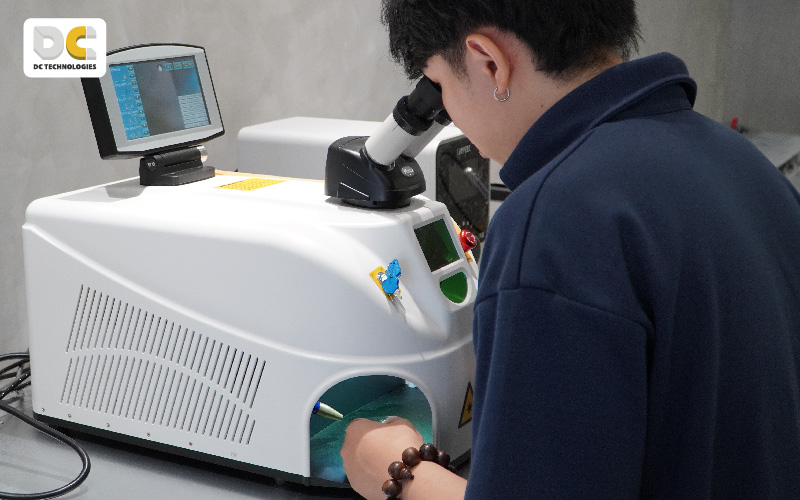

A jewelry welding machine is a specialized device used to weld extremely small components on jewelry made of gold, silver, platinum, or other precious alloys. The machine is designed to create small, precise welds with concentrated heat, without deforming or scorching the metal surface.

>>See more: What is a laser welding machine?

Use a focused laser beam to create extremely small, clean, and precise welds. The heat-affected zone is very small, so it does not deform the components and can weld close to gemstones. Suitable for both high-end crafting and repair.

>>See more: Laser Welding Technology

Use a strong pulsed electric current at a small point to join metals. The welds are small but sufficiently strong, easy to operate, and less expensive than laser welding. Suitable for small jewelry shops and quick repairs.

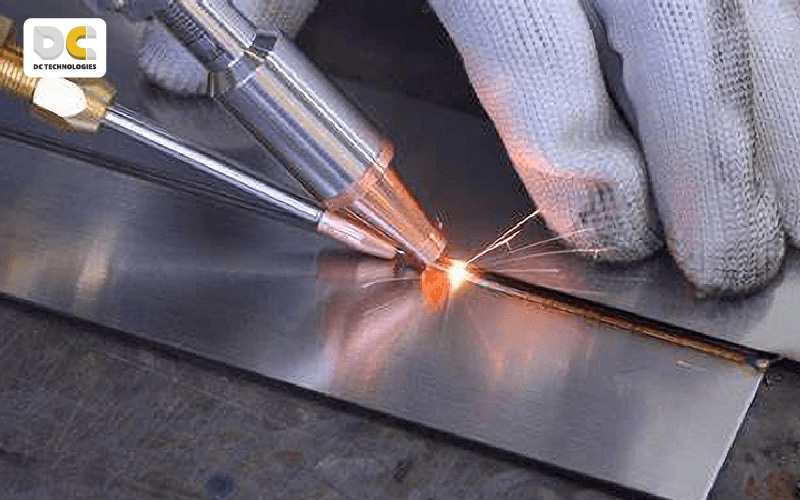

Generate a miniature electric arc to weld thicker components or those requiring high strength. The heat spreads wider than laser welding but is stronger than pulse welding. Commonly used for repairing silver, platinum, or medium-thickness components.

Operate by directly heating the contact area of the metal to join it. Simple in structure and low-cost but less precise, not suitable for very small details. Used for basic repairs or small-scale jewelry shops.

In practice, jewelry welding machines are widely used for many important tasks, including:

>>See more: 200W Laser Welding Machine – An Indispensable Tool for the Jewelry Industry

An industrial welding machine is a specialized device used to join metal components in manufacturing, mechanical engineering, construction, or equipment fabrication. The machine produces strong, durable welds, usually with high power, making it suitable for thick or large-sized components.

Use high-power laser beams to weld thick metals or intricate structures. Commonly used in automotive production, electronic components, and precision engineering.

Use a tungsten electrode and inert gas to precisely weld thin metals or components requiring high aesthetics. Suitable for welding stainless steel, aluminum, brass, and titanium.

Use a welding rod as an electrode to generate an electric arc that joins metals. Suitable for steel, construction projects, and heavy equipment fabrication.

Use continuous welding wire and shielding gas to create strong welds. Suitable for steel, stainless steel, and aluminum in mechanical production, automotive, and steel structures.

Operate by generating heat from electrical resistance, allowing secure connections of electronic components, circuits, and other electrical parts.

Industrial welding machines are widely used across many fields due to their ability to produce strong and stable welds, specifically:

| Criteria | Jewelry Welding Machines | Industrial Welding Machines |

| Purpose | Crafting and repairing jewelry, small and intricate components | Welding metal structures, mechanical parts, industrial production |

| Power | Low to medium (50W–200W) | High (from several hundred watts to several kW depending on type) |

| Technology | Laser, pulse, micro arc | MIG/MAG, TIG, arc, industrial laser, resistance |

| Weld Size | Very small, delicate | Large, strong, durable |

| Precision | Very high, welds almost invisible | Medium to high depending on technology, generally prioritizes strength and durability |

| Heat-Affected Zone | Small, concentrated, does not deform components | Wide, large heat dispersion |

Gold, silver, platinum, or palladium all have different properties. Identifying the main type of metal will help you choose a welding machine with the appropriate power and technology.

Extremely small, hollow, or intricately patterned components require precise laser or pulse welding to ensure a clean weld without deforming the part.

Large workshops or jewelry shops with many clients will need a high-power machine that can operate continuously and reliably, avoiding interruptions during important welds.

If frequently welding near diamonds, rubies, or sapphires, a laser machine with a small heat-affected zone should be chosen to protect the stones and preserve their color.

Authentic machines that are easy to maintain with readily available spare parts help save long-term costs. At the same time, consider your budget to select a machine with the necessary power and features.

Machines that allow adjustment of power, pulse, spot, or speed can handle various types of components and metals, providing flexibility in both crafting and repair.

>>See more: Factors Affecting the Price of Laser Welding Machines Today

DC Technologies specializes in supplying and distributing official laser welding machines from leading international brands such as Elettrolaser (Italy), FASTI (Italy), and Siro Lasertec (Germany), ensuring the best experience for customers.

These products are carefully selected to guarantee quality, high precision, and long-lasting durability, helping jewelers and jewelry shops achieve precise welds without damaging components or gemstones.

In addition, when purchasing welding machines from DC, customers receive:

With DC Technologies, you not only own a high-quality laser welding machine but also gain a comprehensive solution to improve work efficiency and professional jewelry crafting experience.

Jewelry welding machines are indispensable tools in crafting and repairing jewelry, ensuring beautiful, precise welds and saving time. Choosing the right machine depends on several factors.

If you want to invest in high-quality, official laser welding machines, DC Technologies is a trusted provider, offering machines from Elettrolaser, FASTI, and Siro Lasertec, along with technical support, official warranty, and guidance to select the appropriate machine.

With DC, jewelers and jewelry shops gain a complete solution to enhance work efficiency and create the most exquisite, perfect products.

Contact DC Technologies now for a quote and advice on selecting the right laser welding machine for your business.For more details, please contact us at:

Website: https://dctech.com.vn/

Hotline: 0901 958 318

Showroom: 87 Nghĩa Thục, An Đông Ward, Ho Chi Minh City

High-Tech Center, 4th Floor, HUTECH Building, D1 Street, High-Tech Park, Tang Nhon Phu Ward, Ho Chi Minh City

No. 22B O2, Linh Dam Peninsula, Hoang Liet Ward, Hanoi