Hotline: +84 902 588 891

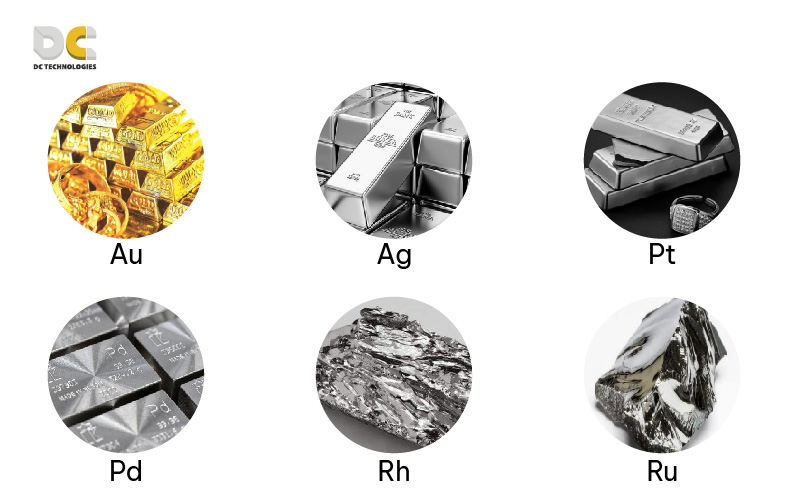

Precious metals are not only valued for investment or aesthetics but are also a fundamental group of materials in many modern industrial sectors thanks to their high chemical stability, durability, and outstanding technical properties. Through this article, DC helps you understand the definition of precious metals, their common types, and their applications in industrial manufacturing.

Precious metals are a group of rare, high-value metals known for their resistance to oxidation, chemical durability, and long-term stability in various environmental conditions. These properties allow precious metals to maintain their quality almost unchanged over time, unlike most common metals.

In industrial manufacturing, precious metals are not only valuable in terms of material worth but also play a critical role in ensuring system safety, precision, and operational stability. Even a slight deviation in composition or purity can lead to significant technical and cost risks.

>> See more: Tips for choosing precious metal distributors in Vietnam

Gold is highly valued for its resistance to oxidation and stable electrical conductivity over time. It is one of the rare metals that can maintain its surface quality and electrical properties almost unchanged in harsh working environments.

In high-precision technical systems, gold is commonly used for electrical contacts, microelectronic circuits, and precision components, where material stability directly determines operational quality.

Silver has the highest electrical and thermal conductivity of all metals, minimizing energy loss during transmission.

In high-performance electrical and electronic systems, silver is a key conductive material, especially in high-power contacts, high-frequency circuits, and devices requiring fast response times.

Platinum stands out for its chemical durability, heat resistance, and structural stability under harsh operating conditions. It is one of the most technically durable precious metals.

For equipment operating in high temperatures and corrosive chemical environments, platinum is almost irreplaceable, especially in catalysts, sensors, and chemical reaction systems.

Palladium has strong catalytic activity and an excellent ability to absorb hydrogen, playing a central role in many modern chemical reactions.

In catalysis and exhaust treatment, palladium is a core material that optimizes reaction efficiency, reduces harmful emissions, and improves energy efficiency.

Rhodium is known for its high hardness, wear resistance, and superior surface durability. It is a precious metal mainly used for protective coatings.

For components that must maintain long-term surface stability, rhodium is used to enhance durability, limit oxidation, and extend product lifespan.

Ruthenium features high hardness and good electrochemical stability, making it suitable for applications requiring high technical precision and long-term durability.

In microelectronics and precision components, ruthenium is used in thin-film resistors, capacitors, and technical coatings to ensure stability and operational reliability.

>> See more: Top 3 rarest precious metals in the world

Precious metals serve as fundamental materials for high-tech industries where precision and stability are vital. Thanks to their purity and ability to maintain physical properties over time, they help systems operate reliably and minimize technical risks.

Another important function of precious metals is their use as industrial catalysts. They enable chemical reactions to proceed faster and more efficiently without being consumed, thereby optimizing energy usage and production costs.

In addition, precious metals are applied in medical and biotechnology fields due to their high biocompatibility, non-reactivity, and long service life.

>> See more: How to preserve and store precious metals

Gold, silver, and ruthenium are used for plating electrical contacts, manufacturing semiconductor chips, and microelectronic components. With stable conductivity and oxidation resistance, precious metals ensure accurate signal transmission and minimize technical errors.

For high-end electronic equipment, precious metals are almost a mandatory standard to maintain long-term reliability.

Precious metal plating increases corrosion resistance, wear resistance, and extends product lifespan. Gold, silver, palladium, rhodium, and ruthenium coatings all provide high technical value.

They are considered the “final protective shield” for components against harsh working environments.

>> See more: Applications of precious metals in advanced electroplating technology

Platinum, palladium, and rhodium are central to industrial catalytic systems. They support exhaust treatment, reduce harmful emissions, and enhance chemical reaction efficiency.

Many modern chemical processes cannot operate effectively without precious metals.

Precious metals are used in biomedical devices, dental restorations, and precision surgical instruments. Their high biological stability ensures long-term safety for the human body.

Precious metals play an important role in fuel cells, hydrogen technology, and clean energy conversion systems. They are key materials for the global trend toward sustainable industrial development.

DC is not only a precious metal supplier but also a technical partner for manufacturing enterprises. Ensuring precise purity and composition helps businesses control quality from the raw material stage.

>> See more: DC – a long-established precious metal distributor

Through modern inspection methods such as spectroscopic analysis, DC helps minimize composition deviations and reduce invisible losses during production.

>> See more: Top 3 most popular spectrometers in 2026

In addition, DC provides consultation on selecting the right precious metal for each industry and process, helping businesses ensure quality while optimizing operating costs.

Precious metals not only have high economic value but also play a crucial role in modern industrial manufacturing, especially in fields requiring high precision and technical durability. Understanding the properties and applications of each type enables businesses to select suitable materials, control costs, and ensure output quality. Therefore, cooperating with professional suppliers like DC is the solution to guarantee standardized, stable, and transparent material sources, contributing to improved operational efficiency and sustainable development.

Fanpage: https://www.facebook.com/dctech.com.vn

Hotline: +84 908 727 235

Showroom: 87 Nghia Thuc Street, An Dong Ward, Ho Chi Minh City, Viet Nam.

High-Tech Center: 4th Floor, HUTECH Building, D1 Street, Saigon Hi-Tech Park, Tang Nhon Phu Ward, Ho Chi Minh City, Viet Nam.

Northern Office: 22B Ơ2 Linh Dam Peninsula, Hoang Liet Ward, Hanoi, Vietnam

Frequently Asked Questions:

Applications of precious metal electroplating in handicraft production