Hotline: +84 902 588 891

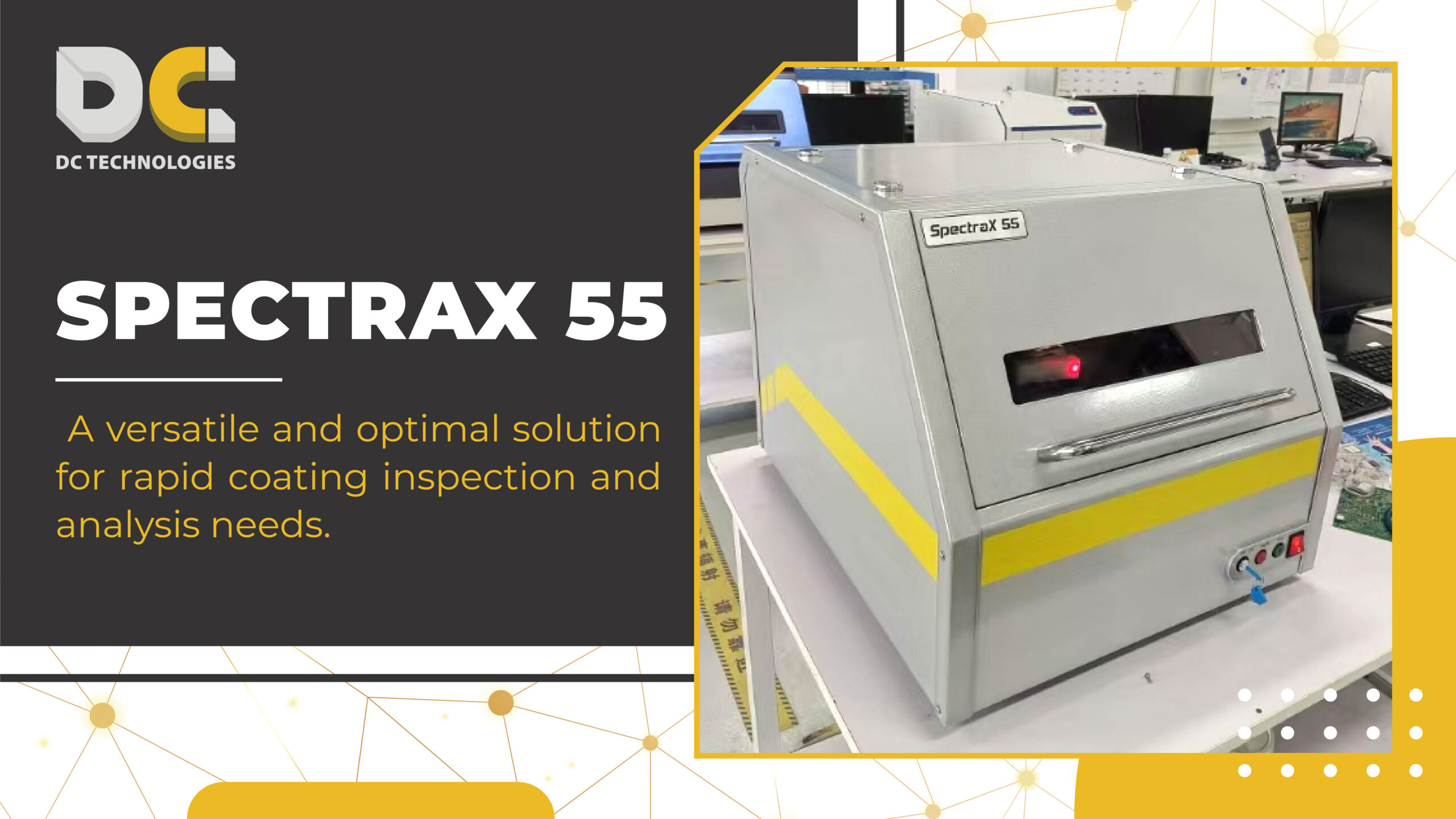

In the modern industry, checking and analyzing coating thickness is crucial to ensuring product quality. Coatings are widely used across various industries, including electronics, jewelry, component manufacturing, and consumer goods. To meet this demand, the SpectraX 55 has emerged as an outstanding solution for coating measurement and analysis. Designed with advanced features, the SpectraX 55 not only measures coating thickness but also supports coating component analysis, improving both quality and production efficiency. Let’s dive deeper into the SpectraX 55 coating thickness analyzer in this article by DC Technologies.

The SpectraX 55 coating thickness gauge is an advanced analysis device optimized for various industries. Below are the key technical specifications of the SpectraX 55:

With these specifications, the SpectraX 55 is undoubtedly an ideal choice for businesses requiring high precision in coating thickness testing and coating component analysis.

The SpectraX 55 not only stands out with impressive technical specifications but also boasts several exceptional features that optimize coating inspection and analysis:

The SpectraX 55 can measure up to five layers of coating, including one base layer, allowing users to analyze multiple types of metal coatings on various materials. Notably, the coating thickness accuracy is up to 0.001μm, a technological highlight that few XRF devices on the market can offer.

One noteworthy feature of the SpectraX 55 is its ability to accurately analyze the alloy composition of coatings, including precious metals like gold (Au), silver (Ag), palladium (Pd), platinum (Pt), rhodium (Rh), and industrial metals like copper (Cu), nickel (Ni), zinc (Zn), and chromium (Cr). This is essential for applications like jewelry plating, electronics plating, and mechanical component manufacturing.

The SpectraX 55 not only helps check coating thickness but also supports testing for hazardous substance content in products according to international standards such as RoHS, WEEE/ELV, EN71, and TCVN. This is particularly important for industries such as electronics and jewelry manufacturing, especially for products intended for children or consumer devices that must comply with strict environmental regulations.

With a high-resolution SDD detector system and a 50kV/1mA micro-focus X-ray source, the SpectraX 55 offers precise and rapid analysis. The automatic filter system with six collimators and a 2MP CCD camera system supports users in accurately aligning measurement positions, ensuring reliable analysis results.

The 3D (XYZ) movement table of the SpectraX 55 can handle a maximum load of 5kg, providing flexibility in measuring larger samples. The ultra-high-definition camera helps align the measurement position, enhancing the accuracy of the analysis process.

The SpectraX 55 comes with intelligent software that allows users to easily perform measurements and analysis without the need for a standard sample. The direct reporting system enables exporting results to PDF or Excel files, making it easier than ever to store and analyze data.

The SpectraX 55 is not only a powerful coating analysis device but is also widely used in various industries:

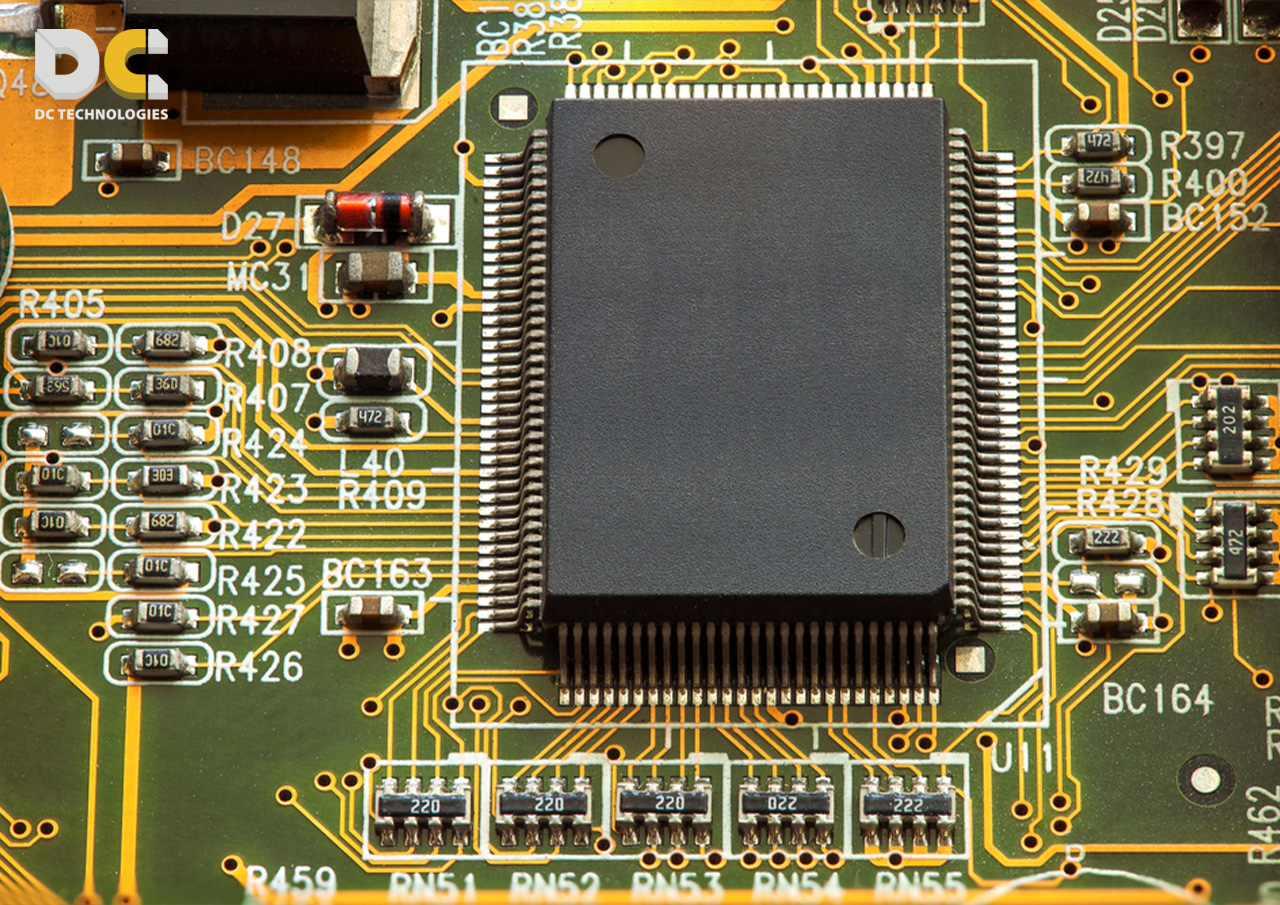

The SpectraX 55 can measure coating thickness on printed circuit boards (PCBs), ensuring the metal coating on electronic components meets high-quality standards. This is critical for ensuring that PCBs and electronic components meet industry standards.

In the mechanical component manufacturing industry, including automotive and household goods production, the SpectraX 55 helps measure the coating thickness on mechanical products, ensuring that the coatings meet technical requirements before going into production.

The SpectraX 55 is highly useful in the jewelry industry, where it can measure the thickness of gold, silver, rhodium, and platinum coatings on jewelry items. It also analyzes the alloy composition of the coating, ensuring the product’s quality and aesthetic appeal.

With the ability to test for hazardous substances in products according to standards like RoHS, WEEE/ELV, EN71, and TCVN, the SpectraX 55 helps businesses in the electronics, jewelry, and consumer goods sectors ensure that their products are safe for use, especially for children.

DC Technologies is proud to be a provider of the SpectraX 55 coating thickness gauge, offering an optimal solution for coating inspection, analysis, and hazardous substance testing. With its advanced technology and outstanding features, the SpectraX 55 helps businesses ensure product quality, increase production efficiency, and comply with international standards for health and environmental protection.

The SpectraX 55 is the ideal choice for businesses looking to optimize their production process and enhance product quality while protecting consumers and the environment. Contact DC Technologies now to learn more about the SpectraX 55 coating thickness analyzer and accurate measurement solutions for your industry!