Hotline: +84 902 588 891

In the world of jewelry making and repair, owning mo dern and powerful equipment is the key to ensuring product quality, optimizing work efficiency, and elevating brand image. Among the most trusted machines by professional jewelry stores today is the LaserX 200W laser welding machine. More than just a welding device, it’s a strategic tool that helps jewelers improve quality and boost productivity. Let’s explore this powerful machine with DC Technologies.

The LaserX SW200Y0 is a high-power machine specially designed for professional jewelers who require efficient and precise repair or fabrication of large quantities of jewelry. With an average power output of up to 200W, it ensures quick, accurate, and highly stable welds—performance that lower-powered machines struggle to match.

Beyond its strength, the LaserX 200W also impresses with its ability to weld intricate details, allowing jewelers to work on delicate, complex designs or gemstone-mounted pieces without compromising overall integrity.

Its durability is another key strength. With a laser lamp lifespan of up to 3 million shots, the machine supports long-term continuous operation with minimal maintenance—perfect for high-volume workshops.

| No. | Specification | Value |

| 1 | Max. Average Power | 200W |

| 2 | Laser Wavelength | 1064nm |

| 3 | Max. Pulse Energy | 100J |

| 4 | Frequency | 1–50Hz |

| 5 | Cooling System | Water |

| 6 | Spot Size | 0.1 ~ 3mm |

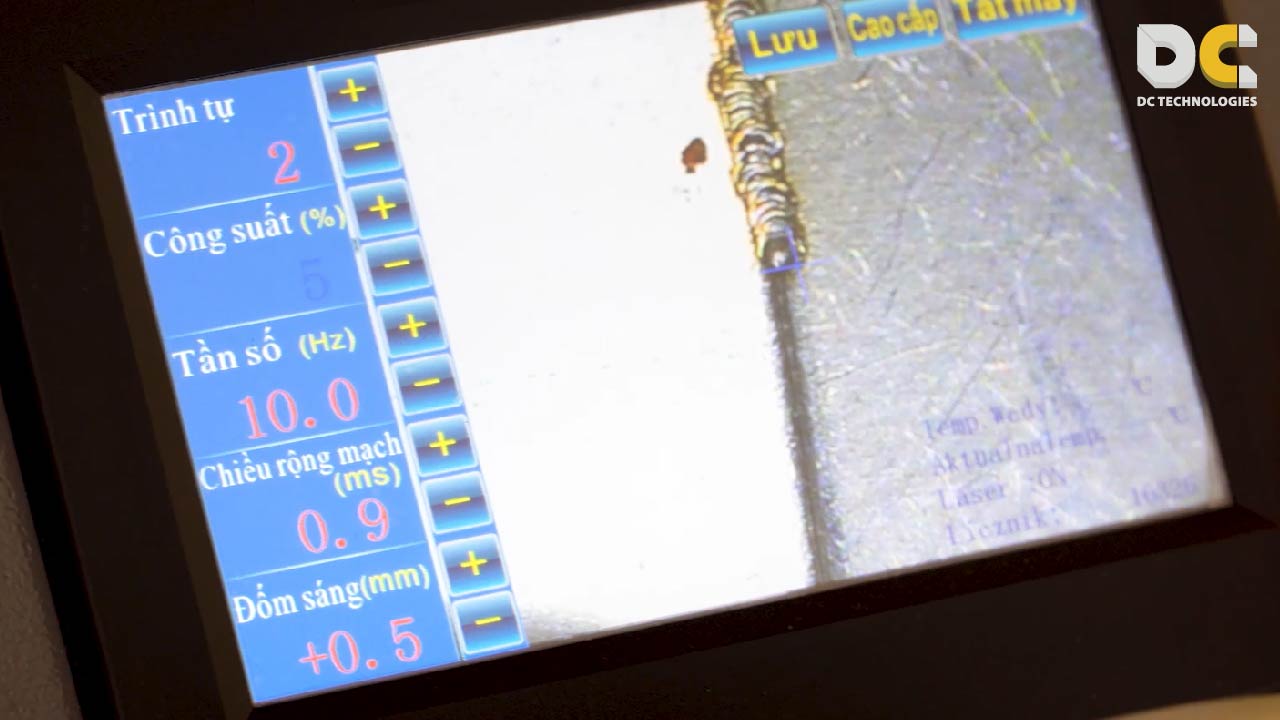

| 7 | Control System | Touchscreen Interface |

| 8 | Power Consumption | ≤6kW |

| 9 | Lamp Lifetime | 3,000,000 shots |

| 10 | Working Environment | Dry, ventilated, clean |

| 11 | Machine Dimensions | 95 x 55 x 65 cm |

| 12 | Power Supply | 220V / 50Hz / 15A |

| 13 | Operating Humidity | 5% – 75% |

This machine is engineered to meet most technical demands and working conditions in jewelry environments.

Thanks to its focused laser beam, the machine delivers highly accurate micro-welds, ideal for fine details and tight spaces where traditional welding methods fall short.

Adjustable spot size from 0.1mm to 3mm allows for precision work on complex or gemstone-adorned jewelry without damaging the structure.

Produces smooth, shiny welds with almost no visible trace. This reduces the need for grinding or polishing and enhances the jewelry’s overall aesthetic and structural integrity.

Narrow heat-affected zones (HAZ) prevent deformation, cracks, or discoloration—common issues with traditional welding—making it safe to weld near gems, pearls, or intricate designs.

With flexible frequency (1–50Hz) and powerful output, welds are completed in seconds—doubling or even tripling productivity compared to older methods.

Welds on gold (10K–24K), silver, platinum, nickel alloys, stainless steel, and titanium. This versatility supports a broader service offering without extra investment.

Modern touchscreen display with intuitive controls makes it easy to operate—even for beginners—ensuring consistent weld quality regardless of operator skill.

Water-cooled system ensures continuous performance under demanding conditions. The laser lamp lasts up to 3 million shots, minimizing replacement frequency.

Though the initial investment is higher, the machine saves on labor, time, and reduces defective output. Most users recover the cost within 6–12 months through increased efficiency and output.

Perfect for stores that handle large volumes daily or during peak seasons. The machine operates continuously without overload—helping meet tight deadlines and uphold your reputation.

Ideal for workshops producing jewelry in batches for dealers or chains. Its speed and reliability ensure fast turnaround and minimal product defects.

Transitioning from low-power or mechanical welders? This machine offers a professional leap in both workflow and brand perception.

For seasoned jewelers, this machine acts as an “extra hand,” helping you refine craftsmanship, reduce errors, and win loyal customers with consistently high-quality results.

In today’s competitive jewelry market, investing in advanced equipment like the LaserX 200W is a long-term, strategic decision. With its strength, precision, and reliability, it’s more than just a machine—it’s a powerful partner for any jeweler looking to optimize operations and deliver outstanding results.

For pricing, promotions, or a demo, feel free to contact DC Technologies. Our team is always ready to help you make the right choice.