Hotline: +84 902 588 891

The bench-top XRF analyzer for RoHS compliance is highly sought after by many businesses, especially in the context of increasingly stringent environmental safety standards, particularly the RoHS directive. Manufacturers need precise analytical solutions to control hazardous elements in their products. With the SpectraX 30 bench-top XRF analyzer for RoHS compliance, companies can easily analyze and control heavy metals in electronic components, jewelry, toys, and many other industrial products. The machine uses advanced X-ray fluorescence (EDXRF) technology, enabling fast, accurate, and cost-effective testing. So, what makes SpectraX 30 special? Why should businesses invest in this device? Let’s explore the details in the following article!

The SpectraX 30 is one of the most advanced X-ray fluorescence (EDXRF) analyzers available today, specializing in analyzing the elemental composition of hazardous substances in consumer products according to RoHS standards such as RoHS/WEEE/ELV/TCVN, effectively serving the electronics, toy, and jewelry industries.

Below are the key technical specifications of the SpectraX 30:

The SpectraX 30 XRF analyzer offers many outstanding advantages, especially for businesses in industries that require testing for hazardous elements. Below are the main advantages of the SpectraX 30:

The SpectraX 30 uses Amptek’s U.S.-made semiconductor probe, which is electrically cooled and does not require liquid nitrogen, unlike many other devices. This not only helps save operating costs but also ensures safe usage.

In particular, the device has an energy resolution of only 145 ± 5 eV, allowing precise analysis from elements like sulfur (S) to heavier elements like uranium (U).

The machine features a modern design with a compact integrated body that is easy to operate and maintain. The software uses advanced SES signal processing algorithms to enhance sensitivity and accuracy in analysis.

Moreover, the user interface is intuitive and supports multiple languages, including Vietnamese, optimizing the user experience.

The SpectraX 30 is designed with a wide sample chamber, allowing for the analysis of a variety of samples with different sizes, ranging from small electronic components to larger products like consumer goods and jewelry.

The proprietary cooling and thermal control technology helps extend the lifespan of the X-ray source, reducing operating and maintenance costs for businesses.

The SpectraX 30 meets international and Vietnamese standards for hazardous element testing. The machine helps businesses comply with directives such as RoHS, EN71 (children’s toy directive), and other environmental protection standards.

With a sensitivity of up to 1 ppm, the machine ensures accurate analysis even for very low limits.

The SpectraX 30 XRF analyzer is specifically designed to analyze hazardous elements across various industries. Common applications of the SpectraX 30 include:

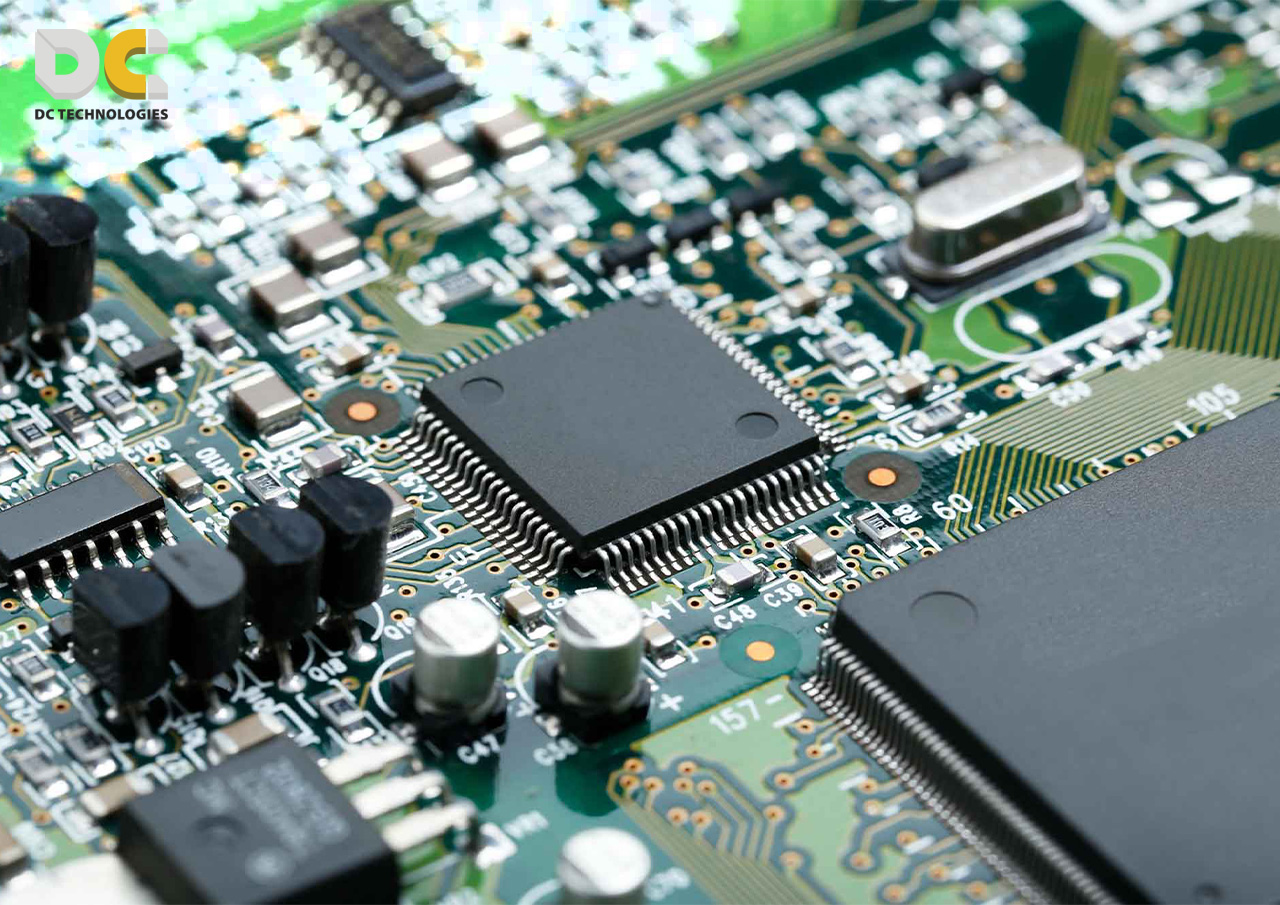

In the electronics industry, the SpectraX 30 is used to test electronic components such as circuit boards, capacitors, cables, and soldering. The machine helps detect elements such as lead (Pb), mercury (Hg), and chromium (Cr VI), ensuring that these products comply with RoHS and CE standards, enabling export to markets like the EU.

Additionally, the SpectraX 30 bench-top XRF analyzer also performs assessments of metal coatings on electrical conector to ensure they do not exceed RoHS thresholds.

The benefits of the SpectraX 30 in the electronics industry are immense. The SpectraX 30 helps businesses analyze and control the levels of hazardous elements in their products, ensuring full RoHS compliance and achieving the CE mark. The CE mark is a mandatory certification for products to be allowed in the EU market, helping expand export opportunities and enhance brand reputation.

Notably, it reduces the risk of product recalls due to RoHS violations. With the ability to accurately and quickly test for hazardous elements in products, the SpectraX 30 helps businesses minimize this risk. Companies can identify and address issues during the manufacturing process, preventing violations and reducing the likelihood of product recalls.

The SpectraX 30 is an ideal tool for testing jewelry products, ensuring that they are free from cadmium (Cd) and lead (Pb), which are elements that can pose health risks to consumers. This helps jewelry manufacturers guarantee safety and maintain their brand reputation.

The SpectraX 30 is also used to test household items, children’s toys, and other consumer products. The machine helps check for harmful substances that may be present in these products, ensuring compliance with legal regulations and protecting consumer health.

DC Technologies Joint Stock Company is the official distributor of the SpectraX 30 in Vietnam. With years of experience in the industry, DC Technologies is committed to providing customers with advanced and effective technology solutions. The company not only supplies quality products but also offers free installation, training, and warranty services.

DC Technologies provides fast technical support, ensuring customers receive assistance within 2-48 hours. Additionally, the company offers free lifetime software upgrades, ensuring customers always have access to the latest features of the equipment without worrying about additional costs.

With the SpectraX 30 XRF analyzer and professional support services, DC Technologies offers businesses an optimized tool for product quality testing and compliance with environmental protection regulations, ensuring consumer safety and safeguarding brand reputation.

The SpectraX 30 bench-top XRF analyzer for RoHS compliance is the perfect solution for businesses in the electronics, jewelry, consumer goods, and many other industries. With advanced technology, smart design, and precise analysis capabilities, the SpectraX 30 helps businesses effectively control hazardous elements in their products, thus protecting consumer health and the environment. Contact DC Technologies now for detailed consultation and to experience the product!