Hotline: +84 902 588 891

In the casting industry, plaster mixing machines play a crucial role in producing high-quality and highly accurate cast products. One of the widely trusted plaster mixing machines today is the EB8 Plaster Mixing Machine. With its advanced features and stable performance, the EB8 plaster mixing machine not only optimizes the production process but also provides long-term benefits. This article will provide a detailed look at the EB8 plaster mixing machine, including its technical specifications, advantages, plaster mixing process, and why DC Technologies is the most reputable supplier of plaster mixing machines.

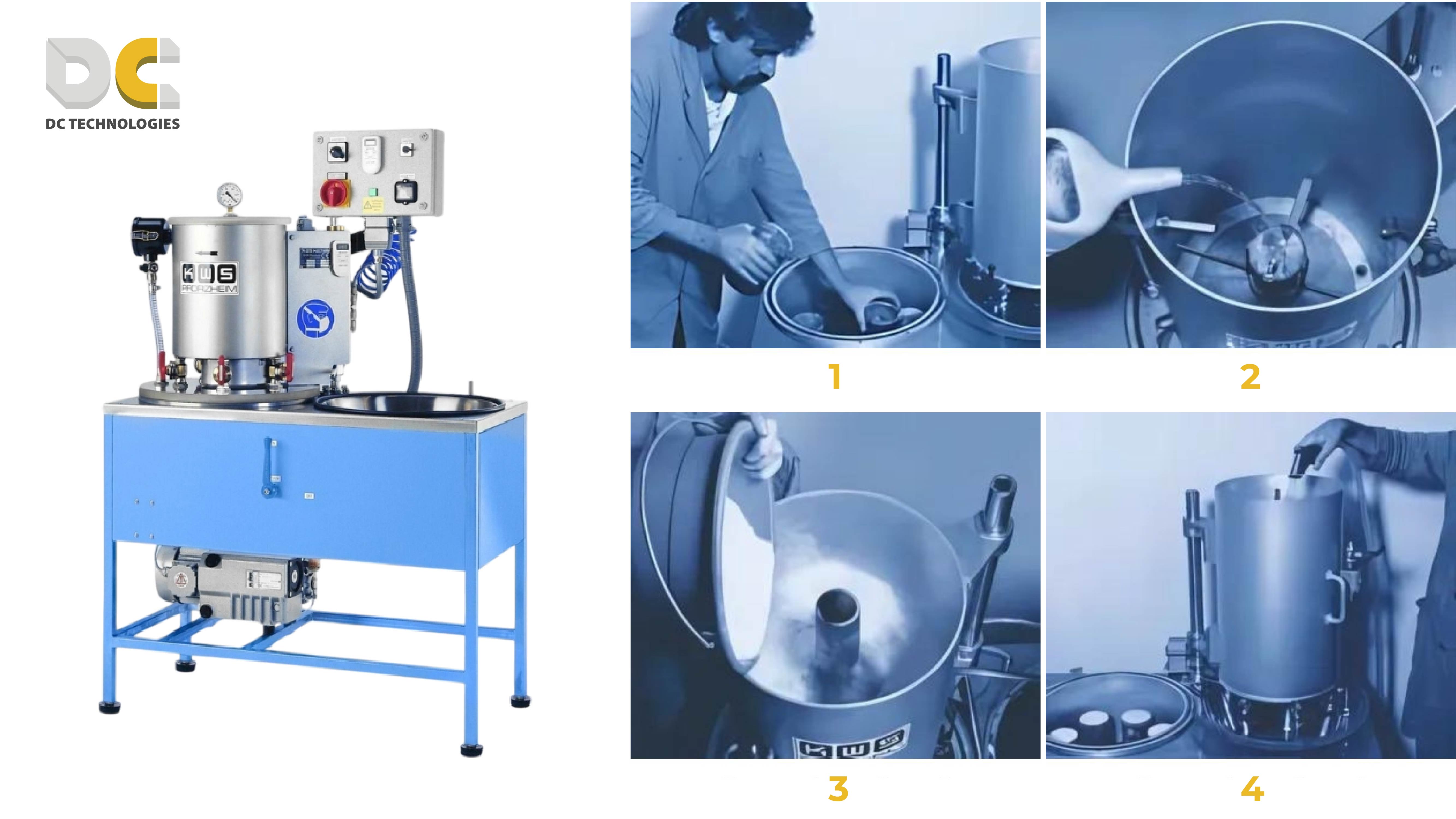

The EB8 plaster mixing machine is designed with advanced features to make plaster mixing more efficient than ever. Below are the key technical specifications of the machine:

The EB8 plaster mixing machine offers numerous advantages that help optimize the casting production process. Here are some reasons why the EB8 is preferred by many production facilities:

The process of mixing plaster with the EB8 machine is simple and quick. Below are the basic steps for using the machine:

DC Technologies is one of the leading reputable companies specializing in supplying EB8 plaster mixing machines and other industrial equipment. With many years of experience in the industry, DC Technologies is committed to providing high-quality products, attentive service, and optimal solutions for businesses in the casting production sector.

The EB8 plaster mixing machine is an ideal solution for optimizing the casting production process, delivering high-quality products, and reducing costs. With its outstanding features and simple operation process, the EB8 plaster mixing machine has proven its effectiveness and reliability in production facilities. If you are looking for a trusted supplier of plaster mixing machines, DC Technologies is the perfect choice to meet all your requirements.