Hotline: (+84) 901 958 318

Precious metals are a group of high value materials that require strict control. Even a minor deviation in quality or origin can result in significant losses. Therefore, selecting a reputable distributor is critically important. In this article, DC outlines the key criteria to consider when choosing a precious metals distributor in Vietnam.

For precious metals, the reputation of a distributor is first reflected in the level of transparency throughout the entire supply chain.

A reliable supplier should provide complete and consistent information regarding material origin, technical composition and applicable standards. These factors directly affect input quality and risk control.

More importantly, transparency should not be limited to the initial consultation stage. Technical information must be clearly stated in documentation and accurately reflected during actual use.

Beyond published commitments, the existing network of partners and customers clearly reflects the real capability of a precious metals distributor.

In practice, precious metals are high value materials that require strict control. As a result, manufacturing enterprises and professional technical organizations tend to maintain long term cooperation only with suppliers that consistently meet quality and service requirements.

Therefore, customer lists and the duration of partnerships are not merely reference information but serve as a basis for evaluating long term reliability.

The quality of precious metals must be ensured not only at the initial transaction stage but more importantly throughout the entire usage period. In reality, many risks arise in subsequent supply batches when quality consistency is no longer well controlled.

A reliable distributor must demonstrate the ability to maintain stable quality across batches, especially when production scales up or output increases. In the long term, this stability helps minimize technical deviations, reduce adjustment costs and ensure consistency across the entire production process.

Precious metals only deliver their full value when used correctly within the appropriate application context. The same material may have significantly different technical requirements across industries, ranging from purity levels to processing stability and equipment compatibility.

Therefore, in depth consulting is not about technical data sheets, but about the ability to analyze actual needs and provide recommendations tailored to each production model. When this factor is ensured, precious metals become a solid foundation for quality control and long term efficiency optimization.

During the use of precious metals, the true value of a distributor often becomes evident when technical issues arise. Timely response, accurate problem identification and appropriate solutions help businesses avoid production interruptions and minimize unnecessary risks.

Supply issues with precious metals rarely occur in initial orders. Risks typically emerge when demand increases or when production plans must be maintained continuously over a long period.

Some suppliers perform well at small scale but begin to experience delays, quality fluctuations or inconsistency as volumes grow. At that point, the challenge is no longer about price but about the ability to maintain stability.

Long term fulfillment capability requires a clear sourcing system, inventory capacity and flexible supply planning. This allows businesses to proactively manage production instead of reacting passively to market fluctuations.

For precious metals, a low price has never guaranteed a correct decision. Small price differences may be accompanied by significant variations in stability, loss rates or usage risks, especially at production scale. Therefore, pricing should be evaluated in relation to quality, service and long term partnership potential rather than through simple quotation comparisons.

In the precious metals industry, true partnership value is formed only when both the business and the distributor share a long term vision. A partner with a cooperative mindset is willing to adjust solutions, share information and provide support as conditions change. In this context, precious metals become a stable foundation for operations and sustainable growth.

DC Technologies is a long established company specializing in material supply and technology solutions, with precious metals as one of its core product groups. With more than 25 years of development, DC Tech has built its position based on practical implementation capability and long term customer trust.

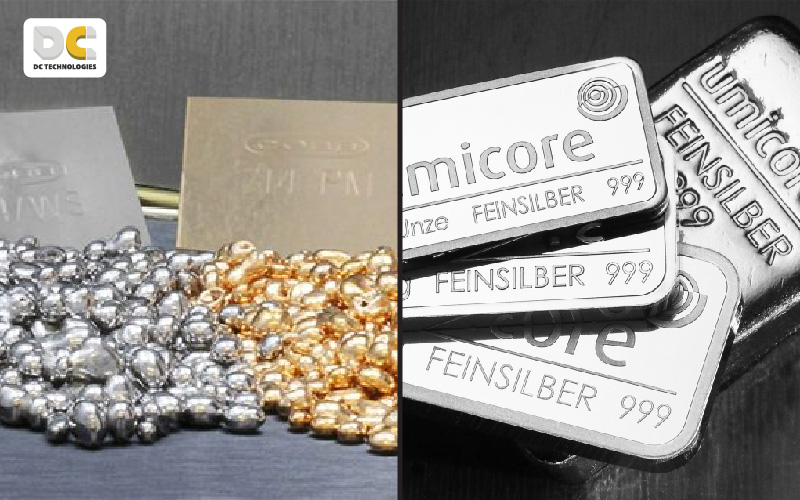

The precious metals portfolio distributed by DC Tech is designed to meet diverse manufacturing and processing needs. Product lines include yellow gold, white gold and rose gold in common fineness levels such as 18kt, 14kt, 10kt and 9kt. In addition, DC Tech supplies platinum, sterling silver 925, gold filled materials, brass and base metals.

Products are selected based on quality stability and practical applicability. Material origins are clearly defined, primarily sourced from markets with strict control standards such as the United States and Germany. Complete documentation and certification accompany each product, enabling customers to effectively manage input quality and meet relevant technical requirements.

>> See more: Top 3 precious metals in fine jewelry making

In addition to supplying precious metals, DC Tech focuses on developing consulting and technical support services tailored to high value materials. Support activities are implemented throughout the usage process to help customers optimize material efficiency and control production risks.

The strength of DC Tech lies in its technical team with over 20 years of experience, deep material expertise and practical application understanding. Combined with flexible support, pricing assistance and suitable credit policies, DC Tech helps businesses maintain stable operations and greater financial flexibility.

In the precious metals sector, DC Tech distributes products from reputable international suppliers such as W R Cobb and Umicore, both of which are known for strict quality standards and material traceability.

In Vietnam, DC Tech currently partners with and supplies major industry players including PNJ, DOJI, SJC, Swarovski and Pranda Group. Long term cooperation with these organizations reflects DC Tech’s stable supply capability and high level of trust in the precious metals industry.

Choosing a precious metals distributor should be considered a long term decision based on reputation, quality and partnership capability. With this orientation, DC Tech is one of the distributors trusted by many businesses in their pursuit of sustainable development.

Contact DC for consultation and preferential pricing.

Contact information: