Hotline: +84 902 588 891

In the jewelry industry, every detail no matter how small reflects the craftsmanship precision and reputation of the artisan. However, the increasing demand for higher levels of intricacy has made crafting and repairing jewelry using traditional manual methods more difficult and time consuming.

The development of Industry 4.0 technology has introduced many modern solutions that make the jewelry production process more accurate and efficient. Among them laser welding machines stand out thanks to their ability to create smooth durable welds without deforming the metal meeting the strict standards of the jewelry industry.

In the article below DC will help you better understand the applications of laser welding machines in jewelry crafting and repair as well as the reasons why this technology is becoming an essential standard in the modern jewelry industry.

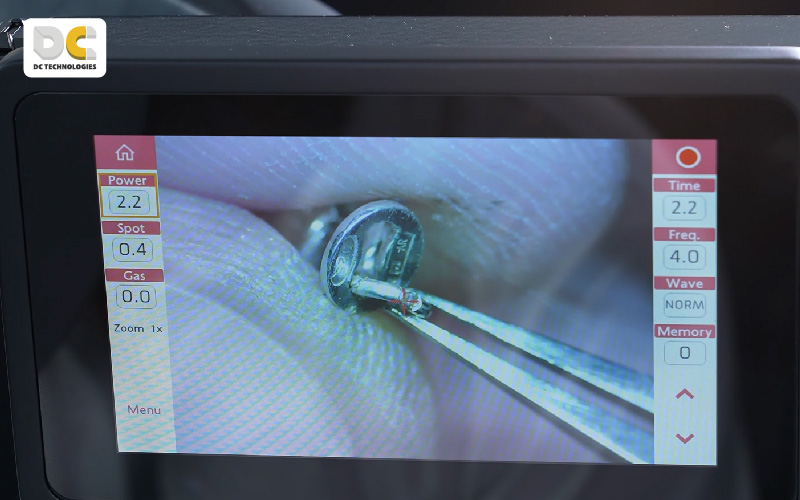

A laser welding machine is a high tech device that uses a high intensity laser beam focused on a single point to melt and join metal materials together.

>>See more: Laser welding technology

In recent years laser welding has increasingly become the top choice in industries that require high precision such as jewelry electronics medical fields or fine mechanics. It is not by chance that this technology is considered a new breakthrough compared to traditional welding but because the benefits it brings are truly superior:

>>See more: Factors Affecting the Price of Laser Welding Machines Today

Laser welding machines bring a significant breakthrough in jewelry crafting thanks to their ability to create intricate welds especially on small components such as links clasps or stone settings. With an extremely precise focused laser beam jewelers can weld precious alloys like gold silver platinum palladium or titanium without worrying about affecting the quality of the metal. One of the most outstanding advantages is the ability to attach and secure stone settings without damaging or discoloring the gemstones something traditional welding methods can hardly achieve. In addition thin hollow or intricately patterned parts can also be welded with high precision helping the jewelry maintain its delicate and elegant design.

>>See more: 200W Laser Welding Machine – An Indispensable Tool for the Jewelry Industry

Not only useful in crafting laser welding machines are also a powerful tool in jewelry repair. Broken or cracked joints can be welded safely without burning discoloration or deforming the metal surface. Laser welding also helps fill holes and restore the surface of old jewelry bringing a like new appearance to beloved items. At the same time technical errors that occur during the crafting process can also be fixed quickly. For small hard to reach components especially on 18K to 24K gold jewelry laser welding proves its superiority thanks to its ability to weld with millimeter level precision while still preserving the refinement of the product.

Power is the key factor that determines weld depth and surface smoothness.

>>See more: Master 4.0 – Benchtop Laser Welder

This is an important factor that enables work on ultra small details such as clasps links or stone settings.

A stable welding machine helps reduce the risk of interruptions and failures during production:

A user friendly laser welding machine allows fast precise and safe operation:

A modern laser welding machine needs to be compatible with various precious metals:

Laser welding machines are not just equipment but have become powerful assistants for jewelry artisans thanks to their ability to fully meet aesthetic requirements. With absolute precision intricate details can be finished with almost no visible marks making the product more beautiful and elegant.

Compared to traditional welding laser welding significantly reduces error rates while improving productivity and overall efficiency. Small thin or difficult components can now be welded perfectly opening new creative possibilities for jewelers.

With these superior advantages investing in a laser welding machine not only helps jewelry shops or workshops save time and effort but also optimizes profitability a smart move for anyone aiming for sustainable growth in the high end jewelry industry.

DC Technologies specializes in supplying and distributing genuine machines from international brands such as Elettrolaser (Italy), FASTI (Italy) and Siro Lasertec (Germany). With a wide range of models from 10W 75W 80W 90W up to 300W they meet the needs and scales from small shops to large workshops.

At DC customers will experience:

Contact DC Technologies today for pricing and consultation to choose the right laser welding machine for your business.

For more information, please contact us at:

Website: https://dctech.com.vn/

Hotline: 0901 958 318

Showroom: 87 Nghi Thuc, An Dong Ward, Ho Chi Minh City

High-Tech Center, 4th Floor, HUTECH Building, D1 Street, High-Tech Park, Tang Nhon Phu Ward, Ho Chi Minh City

22B O2 Linh Dam Peninsula, Hoang Liet Ward, Hanoi City

For more information, visit the link below: