Hotline: (+84) 901 958 318

Among today’s technologies, X-ray fluorescence stands out as a fast, accurate, and non-destructive solution. However, many questions are still being raised: “Is the XRF analyzer truly accurate?”, “Are there large errors when analyzing gold, steel, or complex alloys?”. This article from DC Technologies will help you understand the operating principles, factors affecting accuracy, and international calibration standards to ensure reliable analytical results.

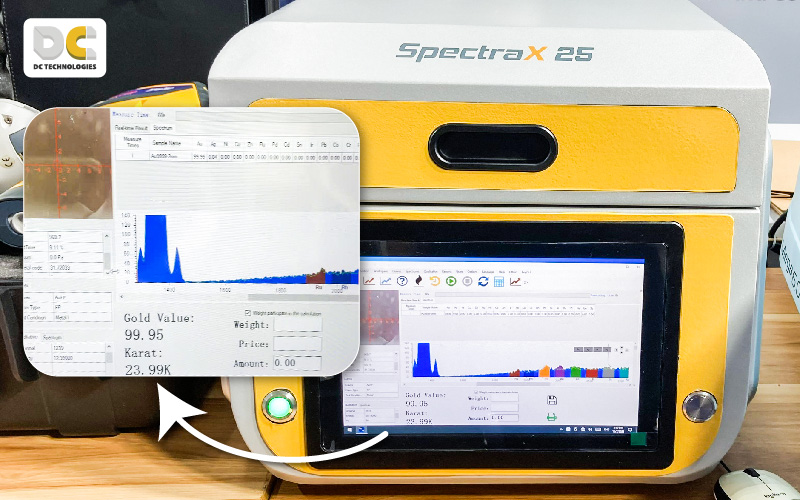

An XRF metal analyzer is a device that uses X-ray fluorescence technology to determine the elemental composition of a material sample. When X-rays are directed onto a metal surface, each element emits a unique fluorescent signal. The analyzer detects and processes this signal to identify the element names and their respective percentage composition in the sample.

Outstanding Advantages of XRF

Thanks to these advantages, X-ray fluorescence technology has become the standard method for rapid analysis in the jewelry, material recycling, and industrial manufacturing sectors.

Accuracy is always a top concern when assessing the performance of any analytical instrument. In practice, a metal analyzer can achieve an error margin of ±0.1%, depending on calibration quality, sample type, and detector technology.

When properly calibrated, spectrometers completely meet the allowable error margin in the jewelry industry as specified in Circular No. 22/2013/TT-BKHCN (dated September 26, 2013) issued by the Vietnamese Ministry of Science and Technology.

In addition, the XRF analyzer also complies with TCVN 7055:2014, which stipulates the following permissible errors:

| Gold content (%) | Allowable error (%) |

| Below 80.0 | ±0.3 |

| From 80.0 to below 99.9 | ±0.2 |

| 99.9 | ±0.1 |

| Above 99.90 | ±0.02 |

Thanks to this level of precision, X-ray fluorescence analyzer is considered the optimal method for high-accuracy applications that require non-destructive analysis — a major advantage compared to traditional chemical testing methods.

In reality, not only the jewelry industry but also industrial manufacturing, plating, mechanical engineering, and precious metal recycling trust X-ray Fluorescence spectrometers as the modern standard for rapid, accurate, and transparent measurements.

Although X-ray fluorescence technology offers excellent precision, measurement results can still deviate if the following factors are not properly controlled:

This is the most crucial factor. TheX-ray Fluorescence spectrometers must be periodically calibrated using certified reference materials (CRMs) — samples whose elemental composition has been certified by reputable international organizations such as NIST (USA), BAM (Germany), or MBH Analytical (UK).

If the calibration is carried out correctly, the analyzer can maintain long-term stability and accuracy.

>> See also: XRF Standard Samples – What You Need to Know Before Using Them.

Rough surfaces, dirt, or oxidation can reduce X-ray reflection intensity and lead to inaccurate results. Therefore, it is recommended to gently clean and ensure the surface is flat before measurement.

The accuracy of X-ray Fluorescence spectrometers largely depends on detector technology and instrument design. Handheld and benchtop models deliver different performance levels depending on detector size and signal processing capabilities.

SpectraX Series, distributed by DC Technologies, is equipped with various detector options tailored for different analytical needs:

Thanks to these advantages, SpectraX analyzers deliver stable and reliable results even with complex alloy samples, meeting strict inspection requirements in both jewelry and materials industries.

Environmental factors such as temperature, humidity, and lighting, as well as operator technique, can also affect measurement results. Even a small misalignment of the sample can cause deviations in the thousandths range.

| Criteria | XRF | Wet Chemistry / ICP / AAS |

| Accuracy | High | High |

| Measurement speed | Seconds | Hours |

| Sample destruction | None (non-destructive) | Yes (sample dissolved) |

| Operating cost | Low | High (chemicals, experts) |

| Ease of operation | Easy, automatic | Requires specialized laboratory |

| Best suited for | Production, rapid inspection, jewelry | Research, certification testing |

With its speed, convenience, and non-destructive nature, XRF is currently the most effective and practical solution for manufacturers, jewelers, and industrial QC laboratories.

The accuracy of X-ray fluorescence analyzer instruments can be consistently maintained when users follow these principles:

By following these measures, the X-ray Fluorescence spectrometers can maintain stable performance and accuracy over many years of operation.

XRF metal analyzers are used not only in the jewelry industry but also across various fields, including:

In Vietnam’s jewelry industry, X-ray Fluorescence spectrometers has become the gold standard for quality control and product valuation.

>> See also: Practical Applications of Spectroscopic Analyzers.

With over 25 years of industry experience, DC Technologies is a leading and pioneering supplier of metal analyzers analytical instruments in Vietnam.

DC Technologies provides:

Backed by a team of professional engineers and a nationwide technical support network, DC Technologies guarantees accuracy, stability, and transparency in every measurement.

X-ray Fluorescence spectrometers represents the most advanced solution for inspection, analysis, and quality control of metal materials in the modern industrial era.

If you are looking for a highly accurate, cost-effective, and user-friendly metal analyzer, let DC Technologies be your trusted partner in building modern testing capabilities and enhancing your brand credibility.